Port of La Spezia: Cold Ironing

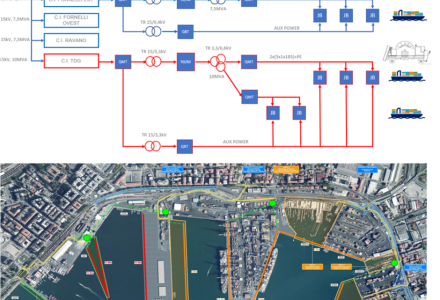

Design of infrastructure for the "cold ironing" of the quays serving the merchant sector, second and third docks of the Port of La Spezia.

PORT ELECTRIFICATION SYSTEMS

Since 2016, we have specifically gained numerous experiences as designers on over 20 port electrification systems with very different complexities and specificities, for a total investment amount of more than €200 million.

As part of these projects, solutions have been developed for the electrification of the quay, and therefore of ship systems, capable of guaranteeing up to 20 MW of power for each single berth and with supply voltages of up to 11 kV, but, above all, with variable network frequencies to allow the adaptability of the system to all the needs of port users and the international reference market. The wide power ranges, together with the diffusion of a wide range of connection systems on board ships, require the designer to consider and prepare systems and processes capable of offering great functional flexibility. To design an effective electrification system, which adequately and effectively reaches every possible power point on board the ship, it is necessary to carry out an in-depth study of the port context, its structural constraints and its operational rules, as well as extend the assessments planning also for the use of any mobile connection solutions. Furthermore, the development of feasibility studies aimed at integrating traditional energy production systems with the introduction of RES generation systems (such as photovoltaic and wind power plants) and new energy storage plants and systems are among the accompanying services provided for the benefit of clients and final plant managers.

Cold Ironing is just one of the possible efficiency measures that can be undertaken in order to achieve ESG and environmental impact objectives. Energy production from renewable sources, energy storage systems, generation and use of green hydrogen, smart and IoT solutions, but more generally a strong digitalisation of port logistics processes, are the real sustainability objectives that the Company and the working group intend to pursue in the coming years.

We follow the principles and procedures set out by the certification standards adopted:

- UNI EN ISO 9001:2015 ‘Quality Management System

- UNI ISO 45001:2018 – Occupational Health and Safety Management System

- UNI EN ISO 14001:2015 – Environmental Management System

- UNI CEI EN ISO/IEC 27001:2013 – Information Security Management System

- UNI/PdR 74:2019 – BIM Management System

Other projects related to this area

A selection of our best projects to fully discover our skills and the passion we put into every challenge. Every result achieved is the result of our commitment to tackling complex challenges and translating customer needs into projects.